Our specialty machines are designed for production processes that demand unique solutions, where off-the-shelf options aren’t sufficient. By blending your expertise and vision with our innovative customization, smart engineering, and technical skills, we deliver high-tech mechanical engineering projects that drive continuous improvement in the manufacturing industry.

Our strength

AXITEC tackles complex challenges, from complete production lines to product handling machines, realizing the best solutions in close cooperation with our customers.

Our strength lies in solving complex automation challenges, where creativity and innovation are essential.

Our focus areas

- Precision positioning

- Robotization

- Machine Control

- Product handling

- Prototyping

- Test Automation

WHAT WE ARE PROUD OF

High-tech mechanical engineering projects

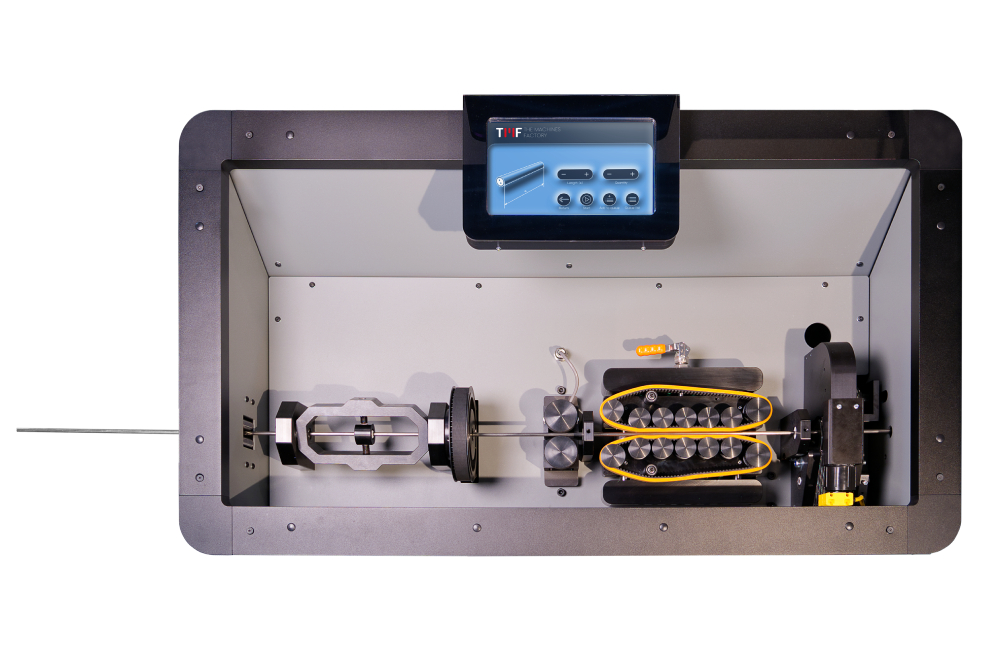

Case: Cable Straightner 1100

The CS-1100 is a compact machine designed for processing cable and tube products in production lines. The process includes a rotary straightener, a feed-through system and a cut-off unit for accurate length cutting.

The straightener is equipped with replaceable PTFE bushings and a quiet servo motor, which supports different diameters and flexibly adjustable speeds. A rotary sensor continuously monitors accuracy without applying pressure to the product, ensuring that the displacement always matches the set value. In case of deviations, the system automatically compensates.

The feed-through system, equipped with coated timing belts, conveys the product accurately. The system centers itself and automatically adjusts to different diameters, while a pneumatic clamping system holds the product securely for precise cutting.

The touch-screen allows the operator to easily manage settings. Optionally, a network module provides remote support and software update capabilities, keeping the machine flexible and future-proof.